We’ve had this question from Tyler who has recently fully rebuilt his 23C engine out of a Massey Ferguson TO35. It looks as though Tyler has looked into most of the potential causes, but is there anywhere else he should look?

Dear Vintage Tractor Engineer,

I want to start by saying your 23C rebuild dvd is great. I have watched it many times trying to solve the problem I am writing you about.

I have a 1959 Massey Ferguson TO35 with a Standard Diesel 23C. I had a retired tractor mechanic totally rebuild the engine for me only to find it has less oil pressure than before the rebuild. He can not find the problem.

The rebuild consisted of new liners, pistons, rings, main and rod

bearings, cam bushings, timing chain and tensioner, total valve job,

injectors and diesel pump. The crank was turned at the rods but the mains are standard. Oversized rod bearings were fitted. The cam bushings are standard.Upon starting at 1400 RPM the engine has about 60PSI of oil

pressure but quickly falls to about 30 PSI and 10 PSI at idle. I have

tried the adjustment screw on the oil filter but it makes no difference.I have cleaned the springs and balls in the oil filter unit, rebuilt the

oil pump, and changed the gauge but none of this has helped. Please give me some advice on what to try next. The tractor has the correct oil in it also. It runs well but has very low oil pressure. Your advice is greatly appreciated.Thanks,

Tyler

Hi Tyler,

It sounds like a nightmare. Nothing worse than taking lots of care with everything (it sounds like you have been very thorough), put it all back together and then to find low oil pressure.

I guess the drop in oil pressure would suggest that it is either leaking

somewhere or one of the bearings is slack. Clearly it is as a result of the engine rebuild as you had good oil pressure before hand (suggesting there wasn’t any problem with the oil pump).

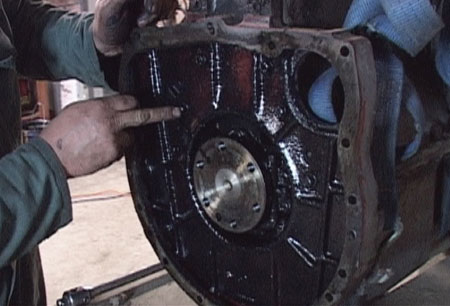

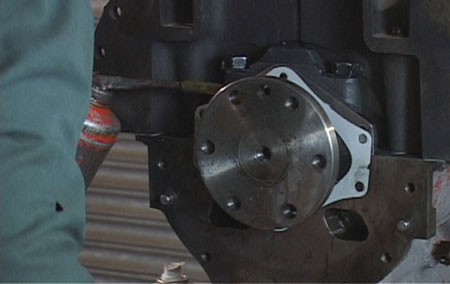

The gasket behind the oil filter elbow is easy to check and could be the first thing to take a look at. Or the gasket behind the front main

bearing/oil pump housing.

You say the pressure starts off at 60 before quickly dropping down. If the pump is all OK and has the potential to get the pressure to 60 then it could be a problem with a shell. Possibly an incorrect shell supplied?

I hope none of that sound condescending to you. It sounds like you have done a good job on the engine and been very thorough but now have got this problem. Really I don’t know the answer, but can only make the above suggestions.

Dismantling the whole engine is obviously a time consuming

job and then it still may not be obvious what the problem is.

Presumably the gauge you are using is correct? I guess it will be, and it is showing a drop. Is the oil pressure pipe that goes between the block and the pressure gauge clear and not blocked in any way?

If I was a betting man I would go for the gasket on the back of the oil pump elbow.

Don’t know if any of that helps.

Let me know if you are able to get to the bottom of the problem.

Regards,

Steve Ridsdale (VTE)

If anyone has any other ideas then let Tyler know in the comments box below